Slovenia-based TPV Group uses Xerafy’s Roswell tags to track auto parts throughout the production process.

SINGAPORE – (13-June-2018) Xerafy, the global leader powering data through innovation to transform industries and lives, is pleased to announce Slovenian automotive components manufacturer TPV Group has deployed Xerafy’s Roswell rugged RFID tags in their manufacturing process to improve the visibility, accuracy, and efficiency of its production processes.

TPV Group supplies body and chassis assemblies, seats and seat components, engine gaskets, and automated guided vehicle (AGV) solutions to leading automotive manufacturers. The company operates five production sites in Slovenia as well as one in Serbia, and has more than 1,200 employees.

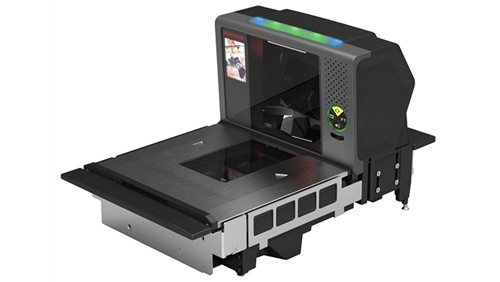

Automated RFID production line to track products through transport and cataphoretic line.

Automated RFID production line to track products through transport and cataphoretic line.

(Source: LOESS)

The company engaged Slovenian automatic identification integrator LEOSS d.o.o. to develop a new RFID-based system to improve TPV’s production and packaging processes. The solution replaced an existing barcode-based system that required more manual effort from employees on the manufacturing floor.

“In order to create a solution that would meet TPV’s requirements, we had to select RFID transponders that could operate while mounted on metal carriers and that would be resistant to the effects of chemicals and high temperatures,” said Franci Nadles, owner of LEOSS. “We also needed to program and configure the fixed RFID readers to avoid cross-reading of the carriers, and develop software that can capture data from the RFID tags and send it to the various control systems that TPV uses in its production processes.”

TPV Group has implemented Xerafy’s RFID transponders and fixed readers and antennas as part of a closed-loop system, so the tags are only read on TPV’s production line as they circulate throughout the facility. The tags are attached to customized product carriers in which various metal parts are suspended. These carriers are transported throughout the production facility both on special carts and an overhead conveyor belt.

Above every workplace is an antenna that reads the RFID tag (highlighted in red).

(Source: LOESS)

Different components may be loaded on each carrier simultaneously, but must be harmonized so the parameters of technological procedures for each production phase are the same for each carrier. Information about the parts on the carrier and production management details are entered into the system as the parts are loaded, and associated to the RFID transponder. A robotic system manages where the carriers are sent for processing using the RFID tag data and automated guided vehicles (AGVs).

Eventually, TPV envisions the RFID tags forming the basis for a “smart factory” that is completely automated.

Because the RFID tags provide high visibility and accuracy, the employees who package the products at the end of production always receive the appropriate product control and packaging instructions.

By re-reading the RFID tag, product information is obtained and the operator is given information about the further procedures on the information display.

By re-reading the RFID tag, product information is obtained and the operator is given information about the further procedures on the information display.

(Source: LOESS)

The Roswell tags have also ensured that TPV can provide full track-and-trace capabilities throughout the production process. During manufacturing, the parts travel through a number of harsh treatment processes, including pre-treatment of the surface, cataphoresis coating, drying at 180 degrees Celsius, and powder coating.

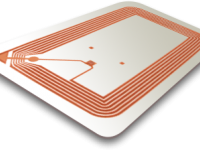

Xerafy’s Autoclavable Roswell RFID Tag w/o bracket (optional)

(Source: LOESS)

The Roswell tags are highly resistant to these processes throughout repeated production cycles, and can be kept in service over a long period of time. The Roswell UHF tags have a read range on metal of up to 5 meters and can withstand temperatures up to 250 degrees Celsius. They are also resistant to paint and chemical exposure.

Xerafy has been working with leading automotive industry companies for years to develop reliable RFID solutions for manufacturing, work in process, and supply chain tracking applications. In addition to the Roswell tag, Xerafy offers a full line of rugged RFID transponders built for harsh auto manufacturing applications, including the Micro X II Automotive – Paint Shop tag.

“We are pleased that TPV Group and LEOSS have been able to leverage our durable RFID tags in this automotive work-in-process application,” said Xerafy CEO and founder Dennis Khoo. “Xerafy’s RFID products are designed to help automotive companies improve productivity and cut costs, and we will continue to focus our development efforts on enabling further industry adoption.”

About Xerafy

Xerafy’s game changing technology enables real time traceability for the industrial market to drive safety, reduce costs and facilitate digital transformation. We power data through products and solutions in Healthcare, Aviation, Manufacturing and Oil & Gas. Over the years, Xerafy has been distinguished by many awards such as the Global Red Herring, EY and Frost & Sullivan. Headquartered in Singapore, Xerafy has offices and operations in U.S., U.K. and China.

About LEOSS

LEOSS is a leading supplier of hardware and software for automatic identification and mobile data collection. Since beginning in 1990, our business has been based on developing bar code and RFID technology. To date we have supported over 3,000 organizations, provided more than 20,000 barcode scanners, 10,000 label printers and over 10,000 handheld computers. Our Mobile Sales solutions are used by more than 150 organizations. Another 400 + use InvOS, an Asset Management Solution, and an additional 50+ use information provided by our Warehouse Management System.

Headquarters are located in Ljubljana, Slovenia, while we also have a subsidiary, LEOSS Adria-kod d.o.o., located in Zagreb, Croatia. The latter is fully supported by the headquarters. Both in the phase of installation and initialization of software and hardware (technical support, consulting, maintenance and updating equipment) and all the needed assistance is provided.

About TPV Group

The TPV Group is a development supplier operating on the global market. Our product programs are contained in three business divisions:

AvtoIN presents our core business. Within this division we develop and manufacture car body and chassis assemblies, seat components and engine gaskets for the needs of OEMs and system suppliers. In addition, we develop and provide complete cost effective solutions for production

logistics management, where automated guided vehicles (AGVs) are the main product highlight.

The Vehicles division contains the program of sales of new and second hand cars and light trailers and the program of overall aftersale services for vehicles users. In our third business division – Trailers – we develop and produce light transport trailers in cooperation with German partner Böckmann. TPV is also one of the partners in the development center SiEVA, within which we develop technological competences and participate on research projects.

https://www.tpv.si/en/tpv-group/

Contact: Michel Gillmann, Marketing Director

michel.gillmann@xerafy.com

www.xerafy.com